Product Features

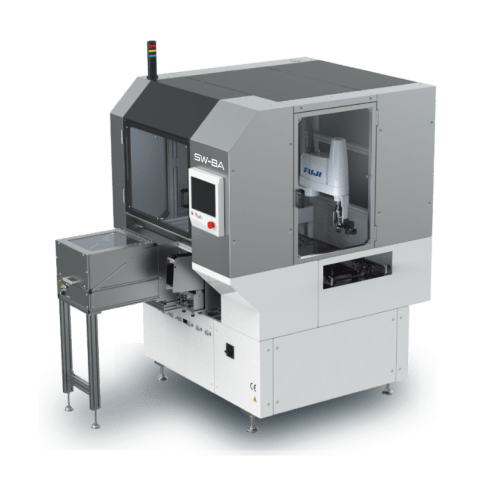

This an all-in-one machine that can handle assembling boards, transferring trays, and distributing parts.

A variety of operations can be performed by a single Robot Cell, from those requiring high accuracy such as for inserting electronic parts into panels, to transferring parts to trays to be supplied to specialized machines, to sorting, assembling, and distributing parts. The various units and vision processing systems are highly versatile, so they can be used as is without the need for dedicated designs. This allows for low-cost introduction by greatly reducing the cost of design, assembly, and other start-up costs.

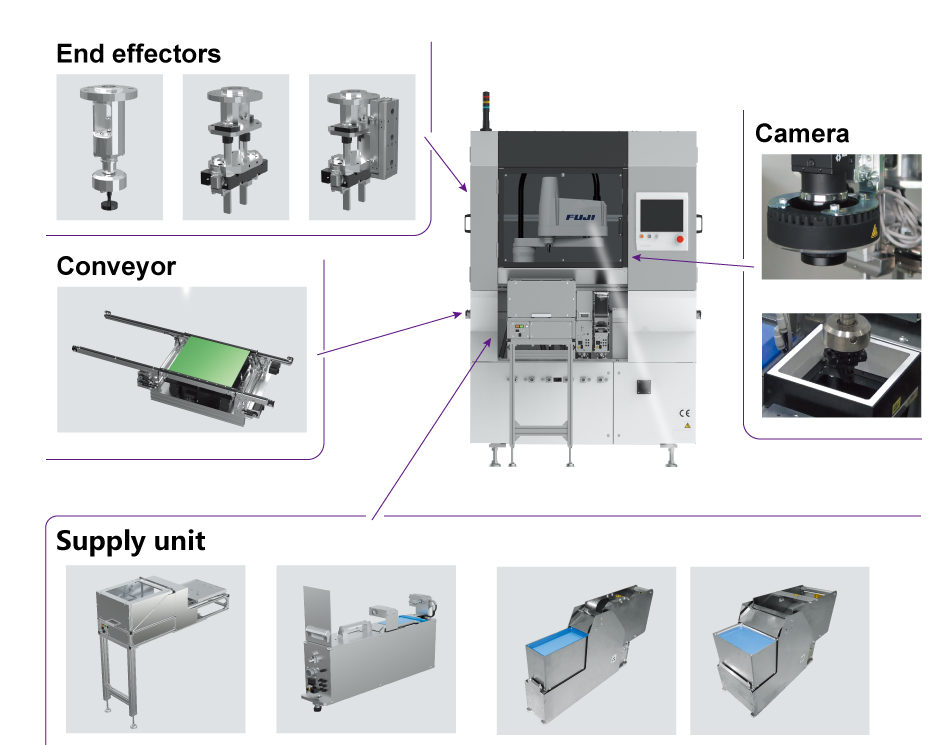

Highly versatile supply units and vision processing system

Conventional dedicated machines, such as inserters, require repackaging into dedicated trays in the supply process. With SW-BA, it is possible to supply parts in the same packaging as they came in by using Robot Cell Kits such as the loose workpiece feeders and tray conveyance unit, as well as the Fuji developed, highly versatile vision processing system.

A wide variety of units are available.

SW-BA is the go-to solution for those who want to automate insertion processes, while unable to commit to large-scale investment at the outset. SW-BA allows you to freely add Robot Cell Kits, so you can add additional functions with small investments while checking the effectiveness of the system. In addition, Robot Cell Kits are available in a versatile and cost-effective lineup to flexibly handle a variety of tasks.

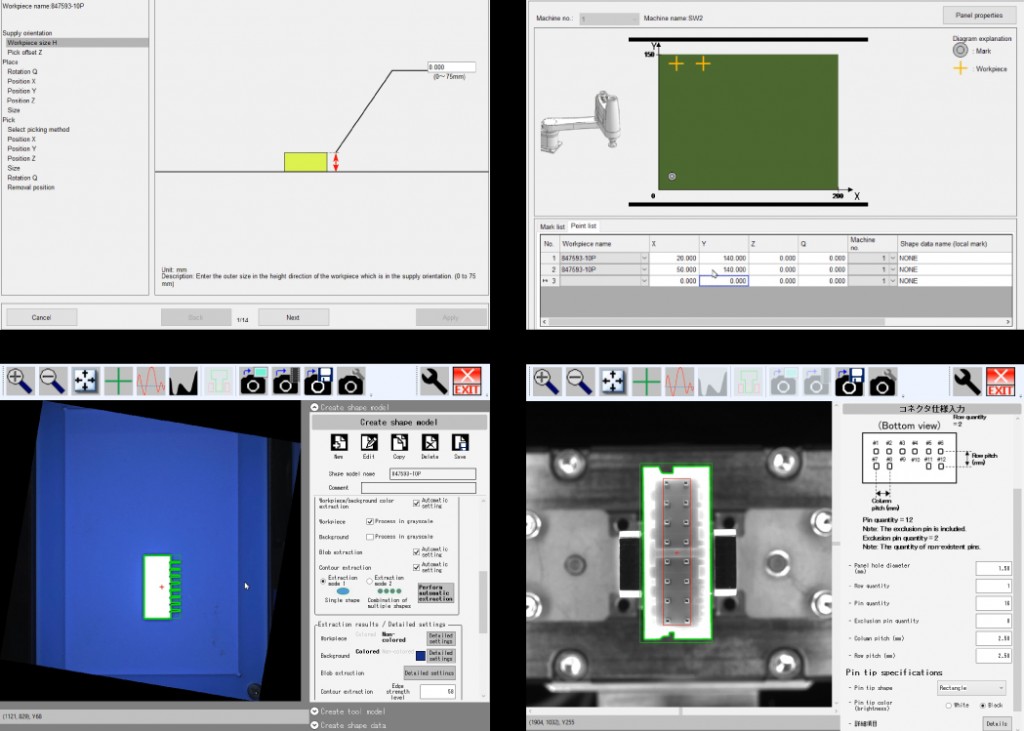

Teaching not required

No expertise required.

It is possible to create production jobs and shape data easily by using the powerful tools equipped as standard that do not require specialized skills and experience. It is possible to add or change the type of product by just adding production jobs and shape data, without the need for teaching, understanding a programming language, or other specialized knowledge.

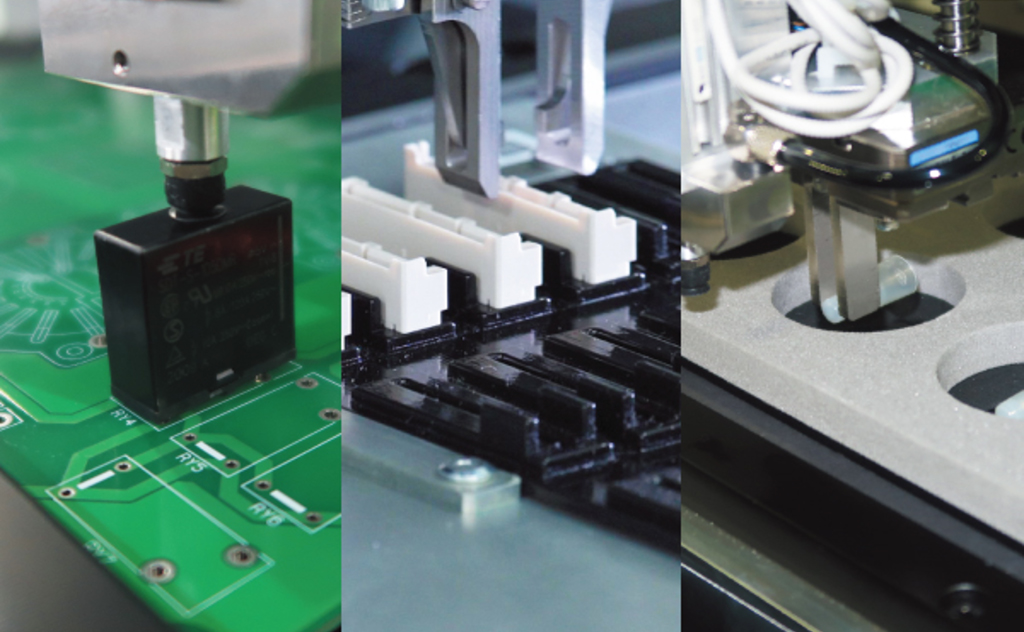

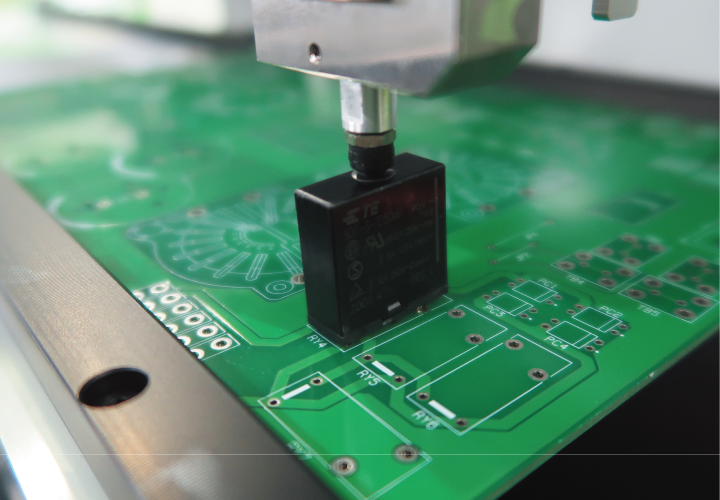

Directly pickup and insert electronic parts such as connectors, capacitors, and relays.

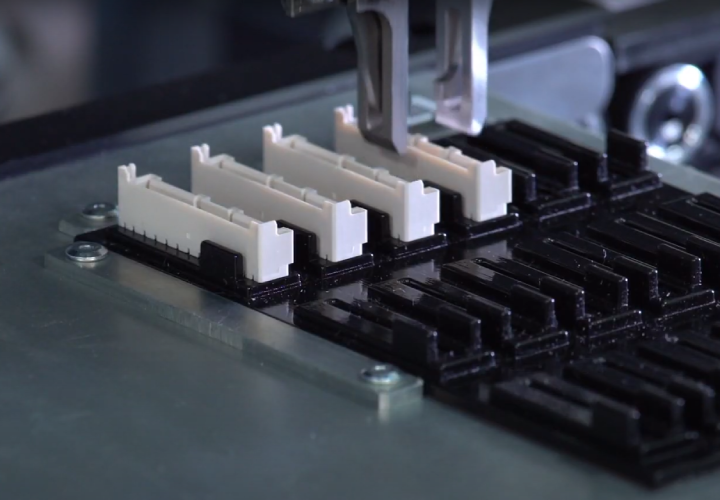

Automates the transfer of parts to dedicated trays for dedicated machines, which is usually done manually as a pre-process.

Perform complex and accurate assembly operations with a variety of versatile units and systems.