Coating/Dispensing System

The Delta 8 is a flexible robotic conformal coating/dispensing system that is ideal for selective coating, potting, bead, and meter-mix dispensing applications. Conceptualized for maximum flexibility, the system can also be configured for custom assembly applications. Maintaining the preferred features of previous workcells, the Delta 8 features a robust overhead three-axis motion platform suitable for inline or batch operations. Improved structural and gantry rigidity have been added for robustness and easier access.

The Delta 8 has many options and integrated features including:

- Patented servo-controlled optional four-axis motion featuring valve tilt and rotate

- Closed-loop process control throughout gantry system

- Multiple dispensing applications or materials in one cell

- Onboard PC for unlimited program storage

- Exclusive PVA programming software designed for the Delta 8

Product Features

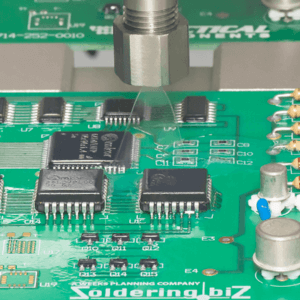

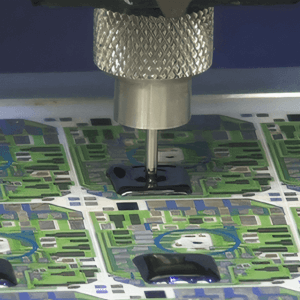

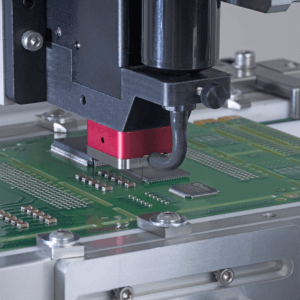

The application of a protective film or layer of liquid onto a PCB, either in selected areas or over the entire assembly. Conformal coatings are applied using an array of technologies such as atomized spray, airless film, needle dispense and jetting.

A two-step process of first dispensing a high viscosity fluid around the perimeter of a device or electronic circuitry, and then dispensing a low viscosity fluid within the perimeter to fully encase the components. The dam can be applied as a single or multi-layer bead depending on the target fill height required.

Applying an epoxy or silicone-based fluid that completely covers a defined area around a flip chip or wire bonded component. This provides mechanical shock and vibration stability, as well as environmental protection from moisture and foreign objects.

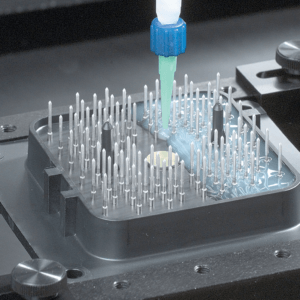

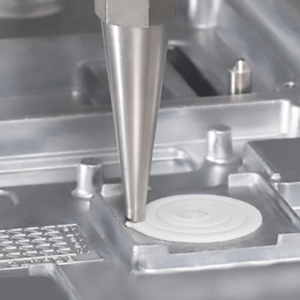

Also known as "form-in-place gasketing," this application dispenses one or two-part liquids into a groove or onto a flange that will cure to form a seal against liquids and gases. This automated process eliminates the task of assembling a die cut or pre-made gasket. Additionally, geometries can easily be modified for other designs.

The process of filling an enclosure that holds electronic circuitry, with a liquid that when cured completely encases the unit. This provides mechanical stability during shock and vibration as well as environmental protection from moisture and foreign objects.

Surface Mount Adhesive (SMA), solder paste, and filled epoxies require accurate deposits to adhere SMT components to a PCB surface. Consistent dot or bead profiles are critical for bonding a broad range of components with a growing emphasis on miniaturization that is achievable with jetting valves or auger pumps.

A thermal interface material ("TIM") fills gaps between mating surfaces with a substance that improves thermal conductivity beyond the air that would have otherwise filled that gap. The TIM acts as a conductive bridge that greatly improves heat transfer between a heat-generating device (e.g. an integrated circuit) and a heat-dissipating device (e.g. a heat sink).

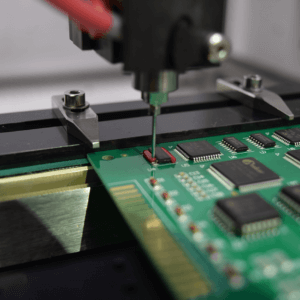

The application of a fluid along one or more edges of an electronic component, such as a flip chip or BGA type package, that flows underneath using capillary action. Underfill is used to prevent thermal mismatch between the component and the substrate, prevent moisture penetration, and to provide mechanical stability during shock and vibration.