Easy and reliable head maintenance. No training required

Automatically cleans and performs a series of maintenance tasks including cleaning the air channels inside the head and inspections. Maintenance quality is more stable and work time can be significantly reduced, compared with manual work. Accurately diagnoses the condition of heads with the enhanced inspection functions.

Product Features

With automatic cleaning, you can get stable and good cleaning results every time without variance and mistakes caused by operators.

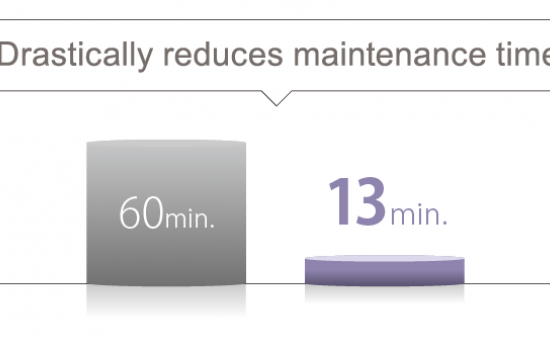

Maintenance time can be reduced by 47 minutes compared to manual cleaning.*1

Operators are only needed for approximately 5 minutes before and after maintenance.

*1: When compared with the time when cleaning a RH20 head.

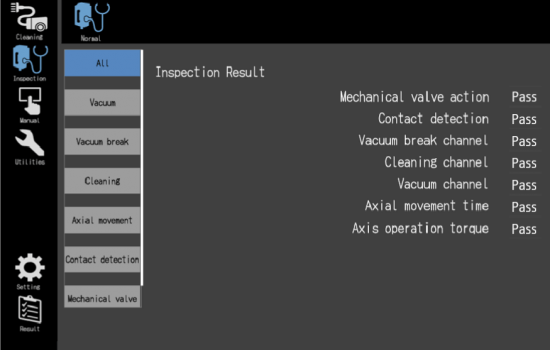

The internal air pressure and flow rate is measured, and each section of the head is inspected to ensure it operates within the specified range after maintenance.

There is also a mode*2 that only performs inspections, allowing you to check whether maintenance is required in a short time.

The inspection results can be checked numerically for each head serial number.

*2: Inspection mode: It is possible to specify the items to inspect.

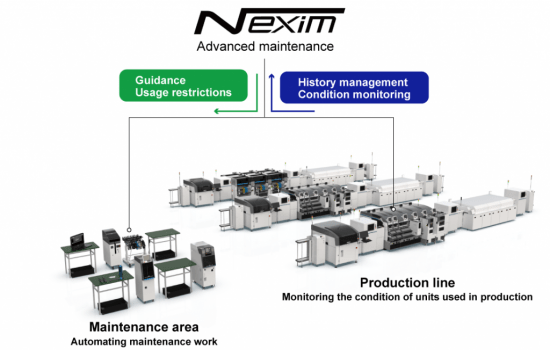

Integrated production system Nexim linked with Auto Head Cleaner-R automatically registers the maintenance history and guides the next maintenance timing.*3

By performing maintenance according to the guidance, production can always be performed with equipment in the best condition and with the minimum work time.

*3: Advanced maintenance in Nexim